Products Details

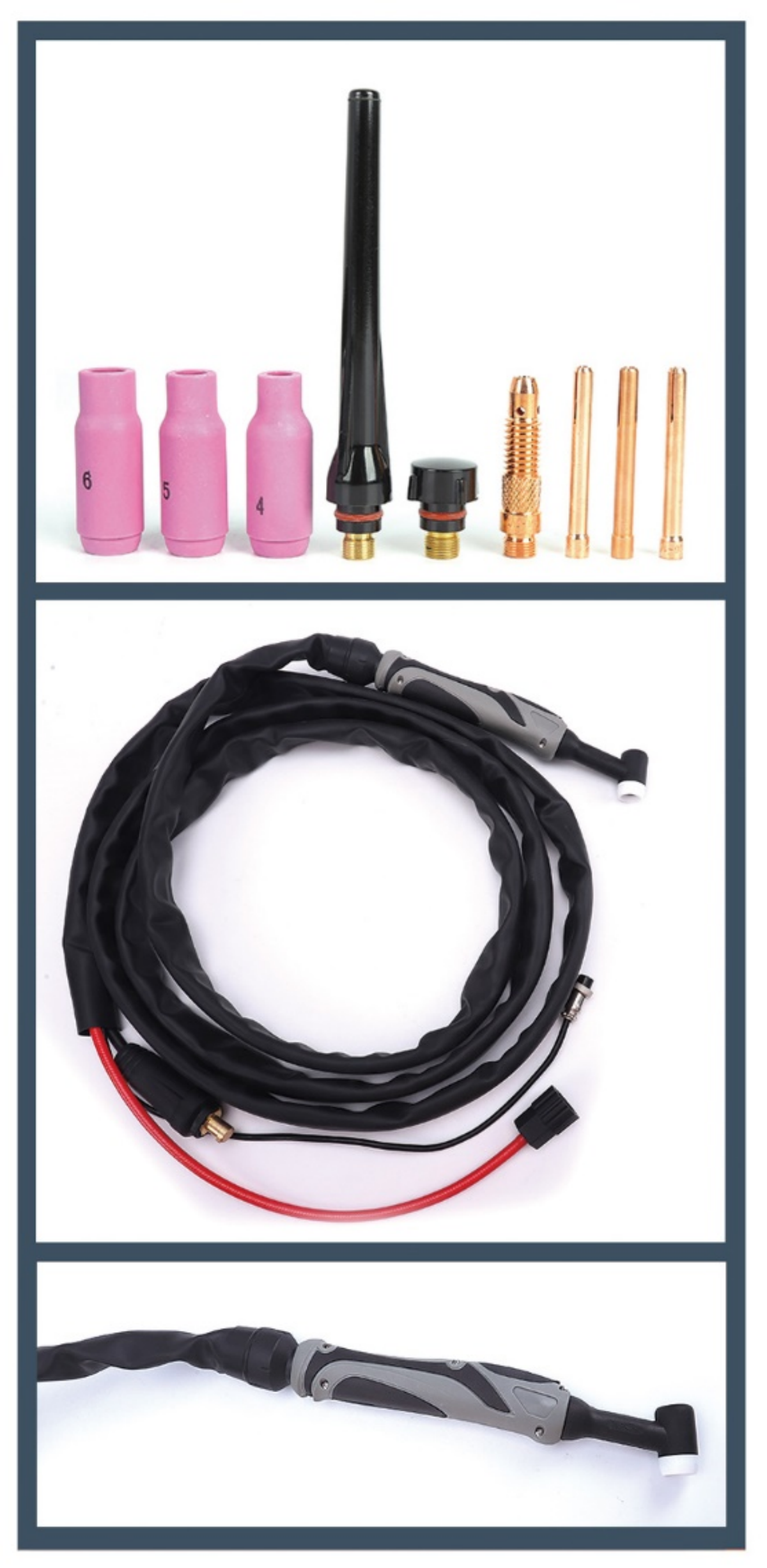

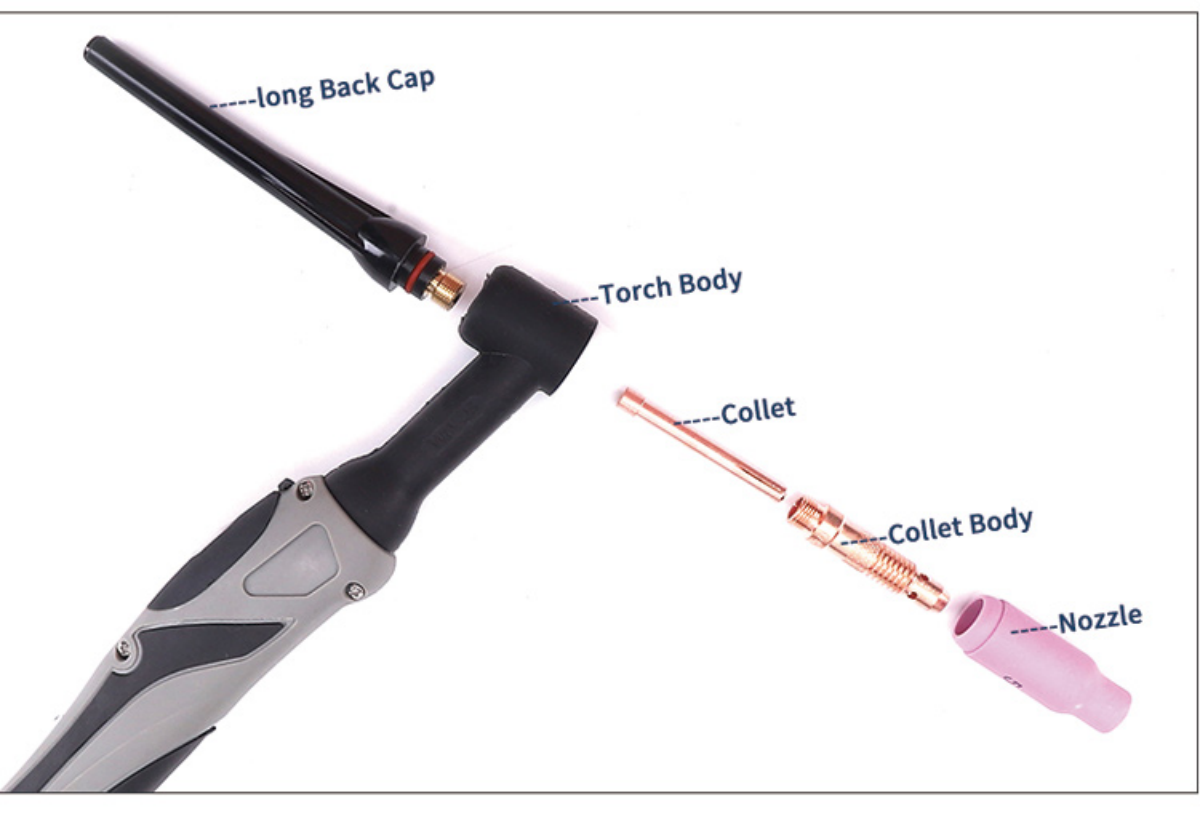

The welding torch diagram  Accessories image resolution Wear-resisting durable quality better

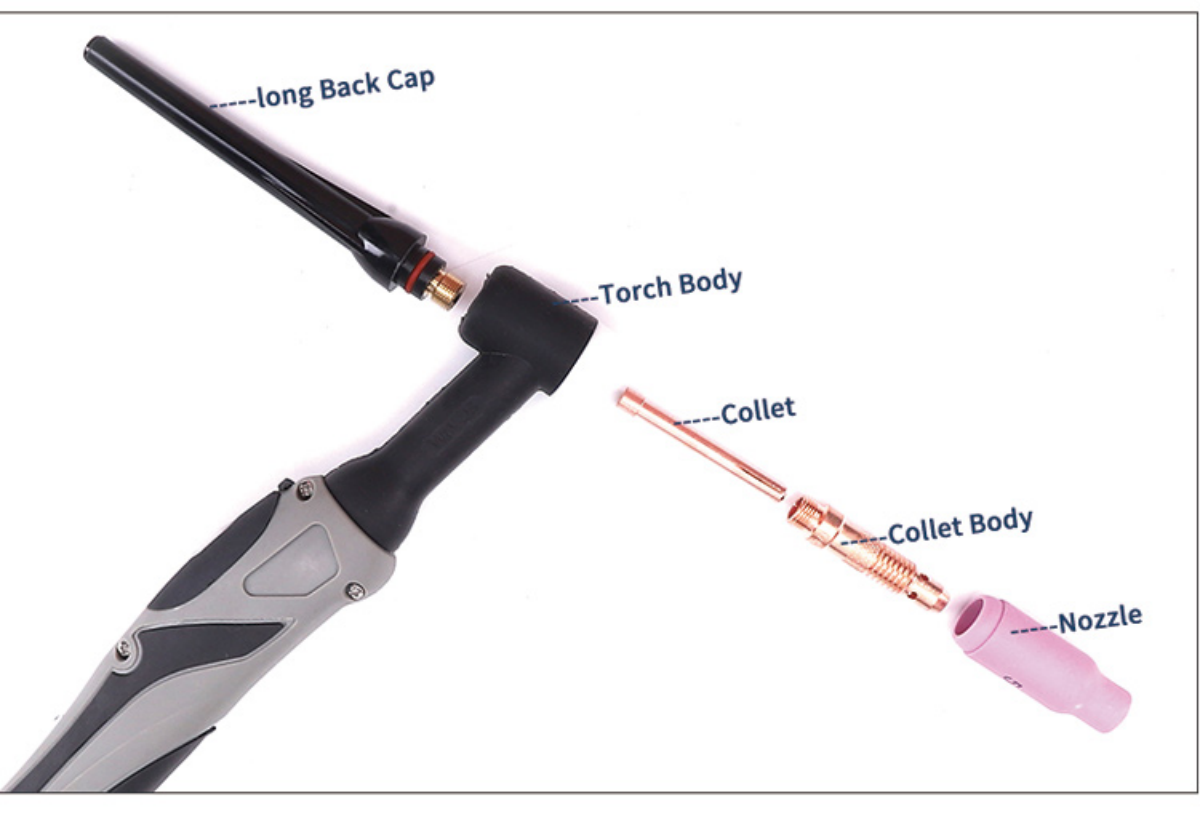

Accessories image resolution Wear-resisting durable quality better  Good cable export quality Each plasma torch cable meets export standards, conductivity,

Good cable export quality Each plasma torch cable meets export standards, conductivity,  Pure copper material The connector is made of brass, which is not hot and has high

Pure copper material The connector is made of brass, which is not hot and has high  Enough square meters long enough cablesEnsure that every plasma torch is a good torch with a few met

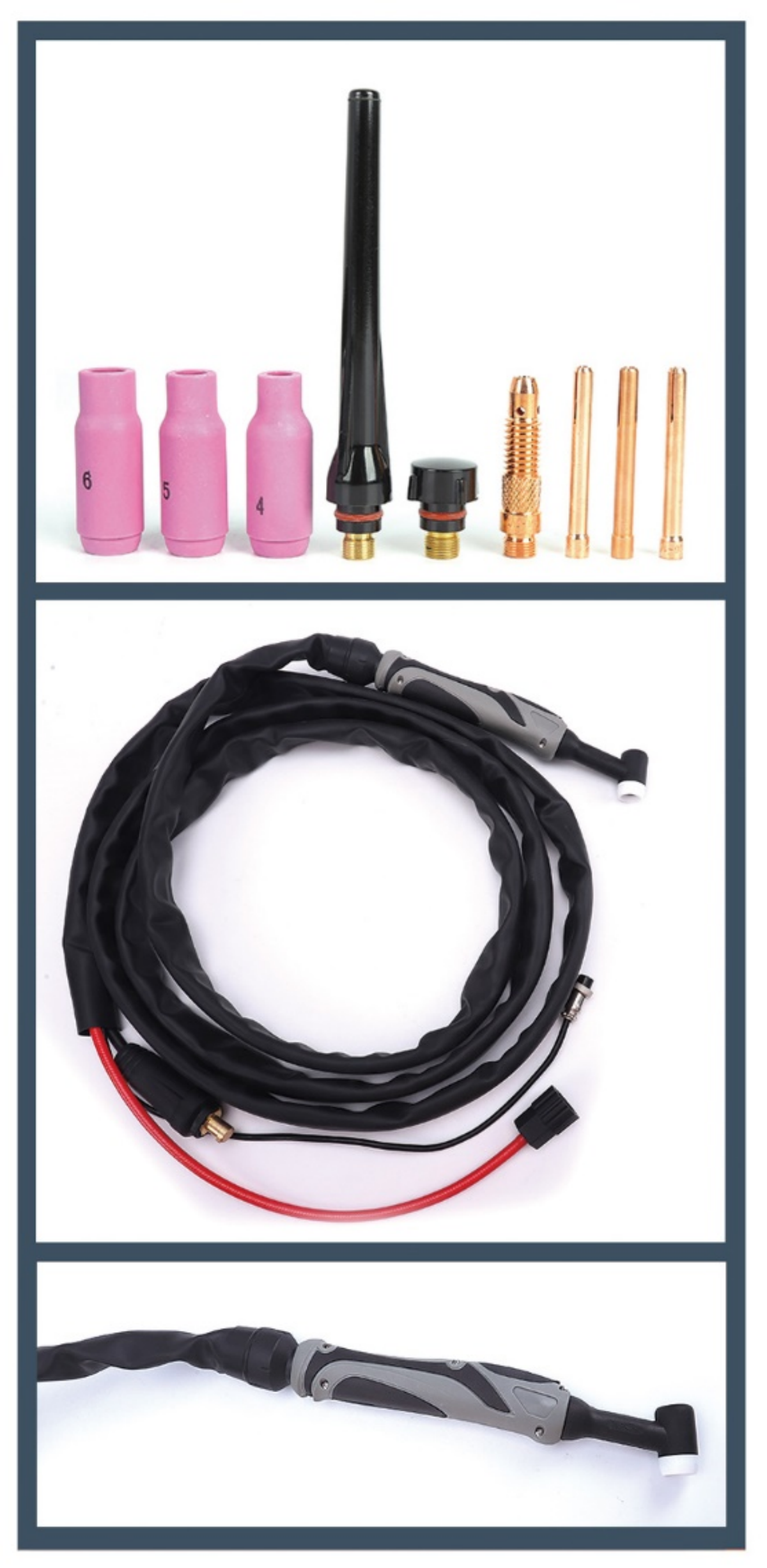

Enough square meters long enough cablesEnsure that every plasma torch is a good torch with a few met 1.Welding torch nozzle 2.Welding torch switch 3.Welding torch handle 4.Welding torch connector

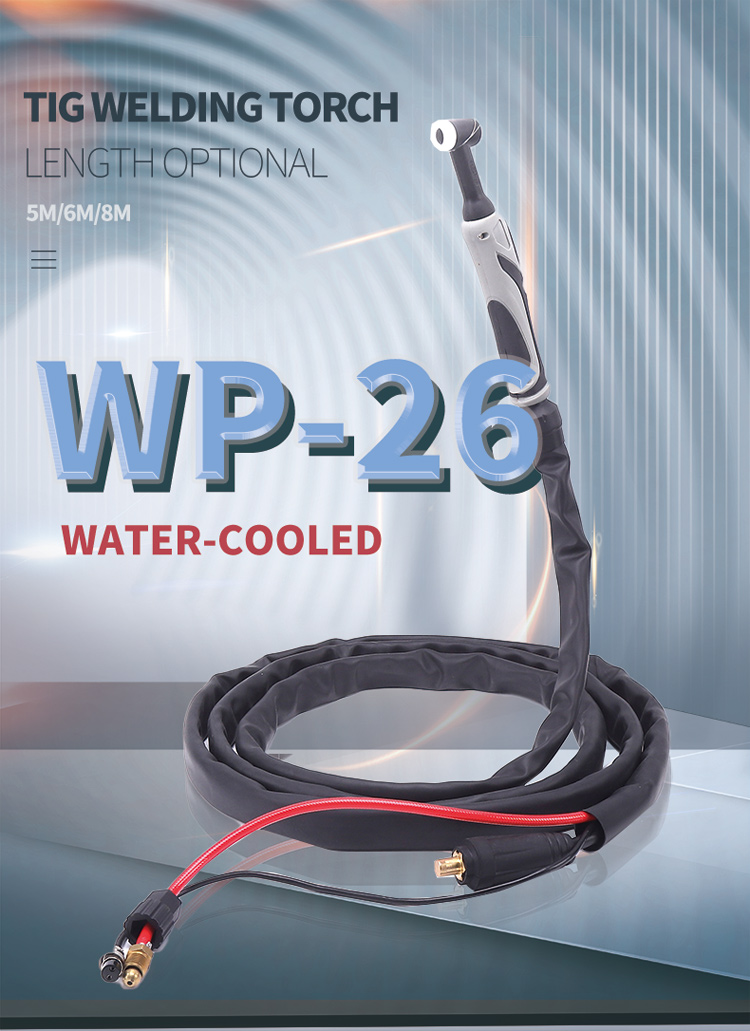

1.Welding torch nozzle 2.Welding torch switch 3.Welding torch handle 4.Welding torch connector  long Back Cap

long Back Cap  Collet

Collet  Nozzle

Nozzle  Collet Body

Collet BodyThe product will more real

|

| Description | Reference N0. |

| Flexible torch boby | WP26F |

| Torch body | WP26 |

| Flexible torch body w/valve | WP26FV |

| Torch body w/valve | WP26V |

| Handle | TIGCN |

| Handle | TIGCN |

| Snap on swith holder | BS-1 |

| Snap on swith holder | BS-1S |

| Handle, smooth | H-200 |

| 2pc.rubber power cable 12.5' | 46V28-2 |

| 2pc.rubber power cable 25' | 46V30-2 |

| Cable Fitting 3/8-24 Thd | T-15PFA |

| Optional 2 pc. power cable 12.5 | 57Y01-2 |

| Optional 2 pc. power cable 25 | 57Y03-2 |

| Gas hose 12.5' Braided | 45V09R |

| 45V10R | Gas hose 25' Braided |

| Swith w/round button | SW-1 |

| Handle,ribbed | H-200R |

| Cable Fitting | D221.R |

| Power cable adapter | 45V62 |

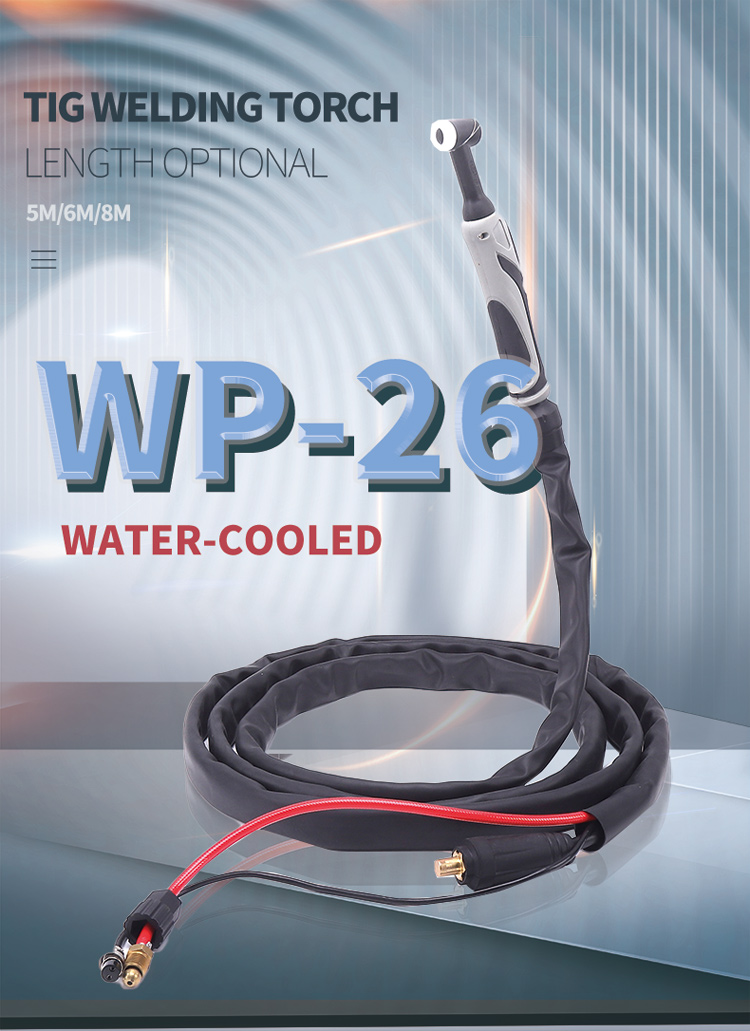

- Premium quality 200-amp air-cooled WP-26 complete TIG welding torch package with 12.5-ft or 25-ft 1-piece rubber power cable for use with most mainstream TIG welders. Shipped as un-assembled.

- 12-pcs torch package includes: 200-amp air-cooled WP-26 series torch body with handle, 1-piece type EPDM rubber power cable hose 46V28R (12.5-ft) or 46V30R (25-ft), Nylon cable cover with zipper; brass cable adapter 45V62 and accessory kit (1/16" and 3/32" collets, collet bodies, ceramic cups and back caps).

- Silicone rubber insulated torch bodies are designed for long lasting service. Available head types: WP-26 (regular), WP-26F (flexible head), WP-26V (head with gas valve) and WP-26FV (flexible head with gas valve).

- 200-amp air-cooled WP-26 series TIG torches are excellent for TIG welding on medium to heavy gauge materials. With brass cable adapter 45V62 to connect the torch to gas tank and welding machine with standard 1/2" threaded output stud. Ideal replacement for most mainstream welders like Lincoln, Miller, ESAB, CK, etc. See all listed pictures for torch parts and rear plug. CHECK YOUR TIG WELDER FOR MATCHING.

TIG WELDING APPLICATIONS The TIG process is particularly suitable when small thicknesses of material, starting from a few tenths of a millimetre, are to be welded. However, it is not possible to weld thicknesses over a few mm (2-3 mm for steels) with a single seam (hence, generally, it is not used to weld thicknesses greater than 5-6 mm). Therefore, considering low productivity, it is often used to make the first seam of a joint, while filling is subsequently carried out with higher productivity processes. Given the characteristics of its procedure, it can be used in any position and can be used for continuous or spot welding. It is not advisable to use this procedure in outdoor locations, as even a moderate wind can cause dispersion of the protective gas.

TIG WELDING APPLICATIONS The TIG process is particularly suitable when small thicknesses of material, starting from a few tenths of a millimetre, are to be welded. However, it is not possible to weld thicknesses over a few mm (2-3 mm for steels) with a single seam (hence, generally, it is not used to weld thicknesses greater than 5-6 mm). Therefore, considering low productivity, it is often used to make the first seam of a joint, while filling is subsequently carried out with higher productivity processes. Given the characteristics of its procedure, it can be used in any position and can be used for continuous or spot welding. It is not advisable to use this procedure in outdoor locations, as even a moderate wind can cause dispersion of the protective gas.

External Turning Tool,

PT40 40Amp With Low Frequency,

Tungsten Drill Tool,

HSS cutting tools,

U-Slot Three-Blade Aluminum Alloy,

Air Cooled Welding Torch,

Ceramic Nozzle,

Mig Torch Miller M150,

PSF405,

Swiss Lathe Carbide Turning Too,

Accessories image resolution Wear-resisting durable quality better

Accessories image resolution Wear-resisting durable quality better  Good cable export quality Each plasma torch cable meets export standards, conductivity,

Good cable export quality Each plasma torch cable meets export standards, conductivity,  Pure copper material The connector is made of brass, which is not hot and has high

Pure copper material The connector is made of brass, which is not hot and has high  Enough square meters long enough cablesEnsure that every plasma torch is a good torch with a few met

Enough square meters long enough cablesEnsure that every plasma torch is a good torch with a few met 1.Welding torch nozzle 2.Welding torch switch 3.Welding torch handle 4.Welding torch connector

1.Welding torch nozzle 2.Welding torch switch 3.Welding torch handle 4.Welding torch connector  long Back Cap

long Back Cap  Collet

Collet  Nozzle

Nozzle  Collet Body

Collet Body  TIG WELDING APPLICATIONS The TIG process is particularly suitable when small thicknesses of material, starting from a few tenths of a millimetre, are to be welded. However, it is not possible to weld thicknesses over a few mm (2-3 mm for steels) with a single seam (hence, generally, it is not used to weld thicknesses greater than 5-6 mm). Therefore, considering low productivity, it is often used to make the first seam of a joint, while filling is subsequently carried out with higher productivity processes. Given the characteristics of its procedure, it can be used in any position and can be used for continuous or spot welding. It is not advisable to use this procedure in outdoor locations, as even a moderate wind can cause dispersion of the protective gas.

TIG WELDING APPLICATIONS The TIG process is particularly suitable when small thicknesses of material, starting from a few tenths of a millimetre, are to be welded. However, it is not possible to weld thicknesses over a few mm (2-3 mm for steels) with a single seam (hence, generally, it is not used to weld thicknesses greater than 5-6 mm). Therefore, considering low productivity, it is often used to make the first seam of a joint, while filling is subsequently carried out with higher productivity processes. Given the characteristics of its procedure, it can be used in any position and can be used for continuous or spot welding. It is not advisable to use this procedure in outdoor locations, as even a moderate wind can cause dispersion of the protective gas.