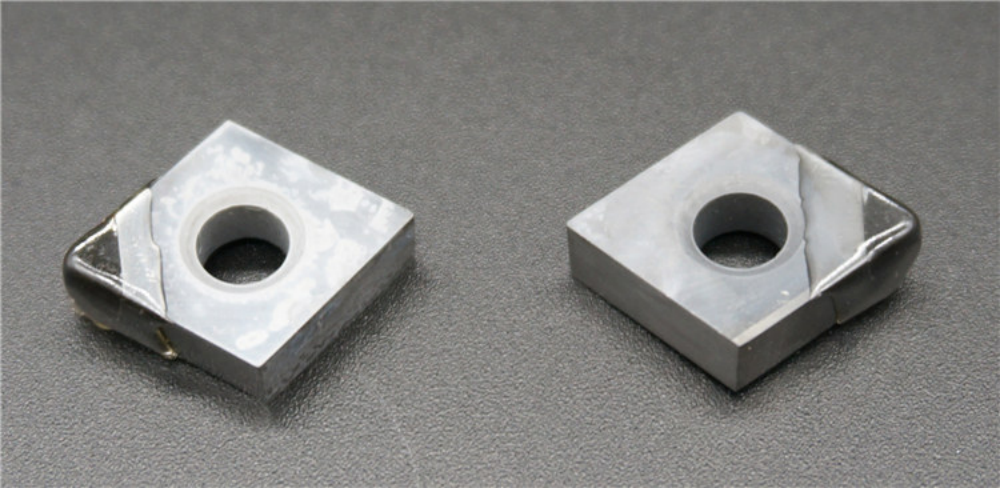

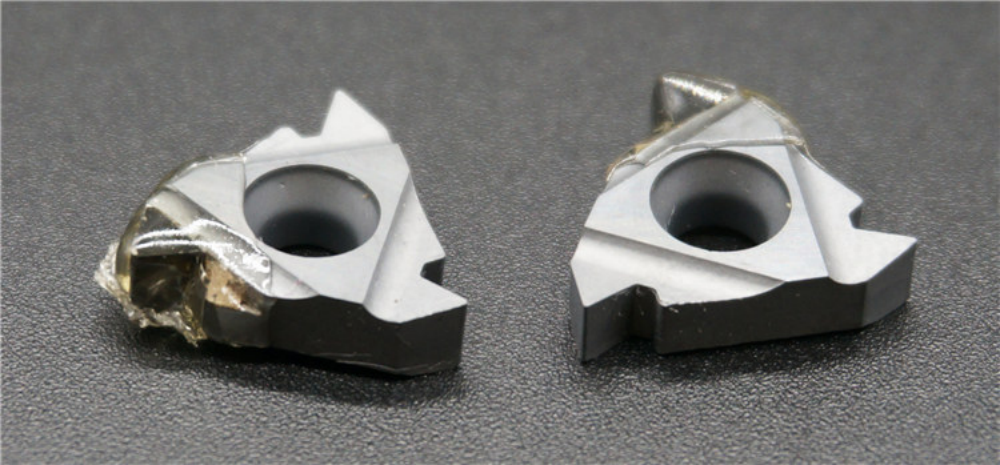

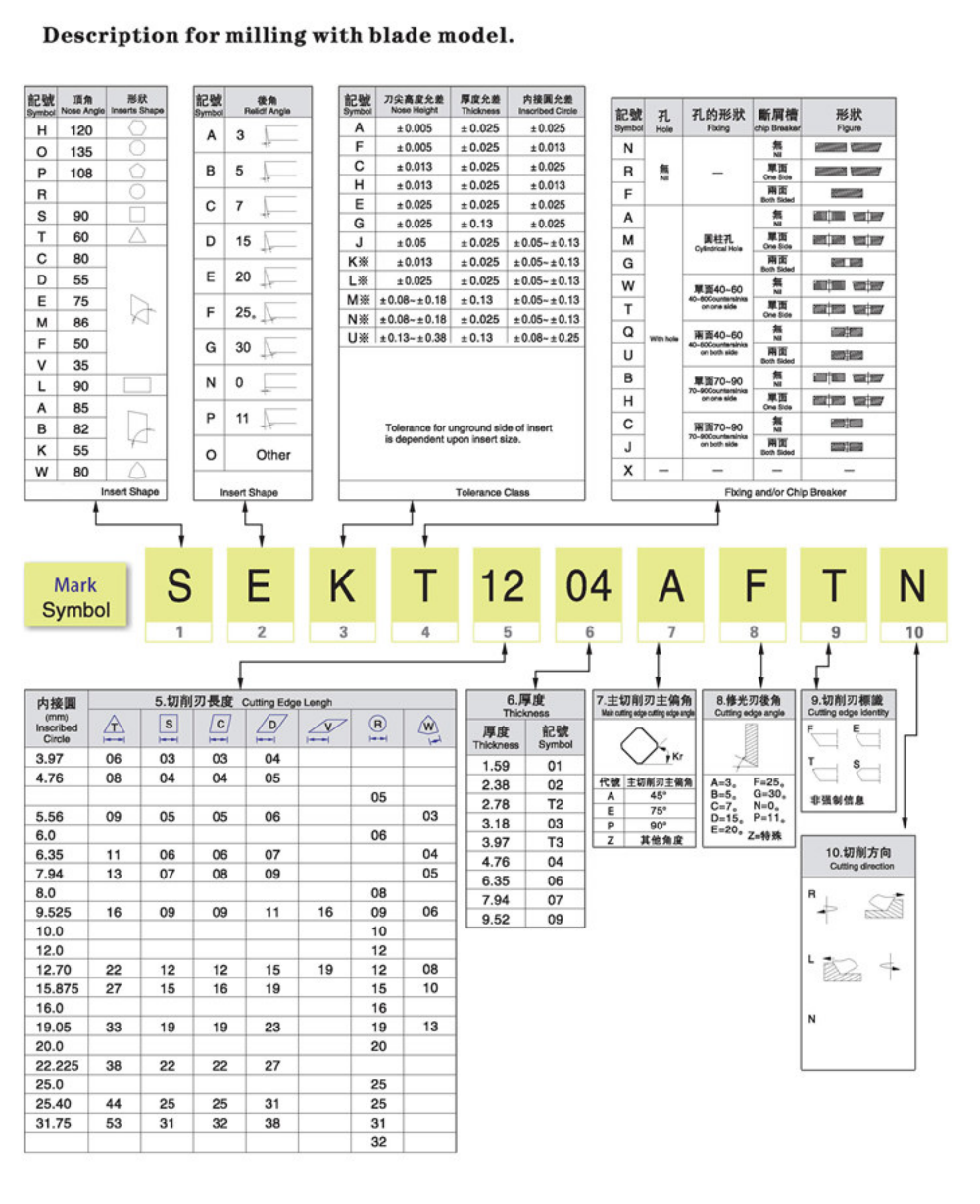

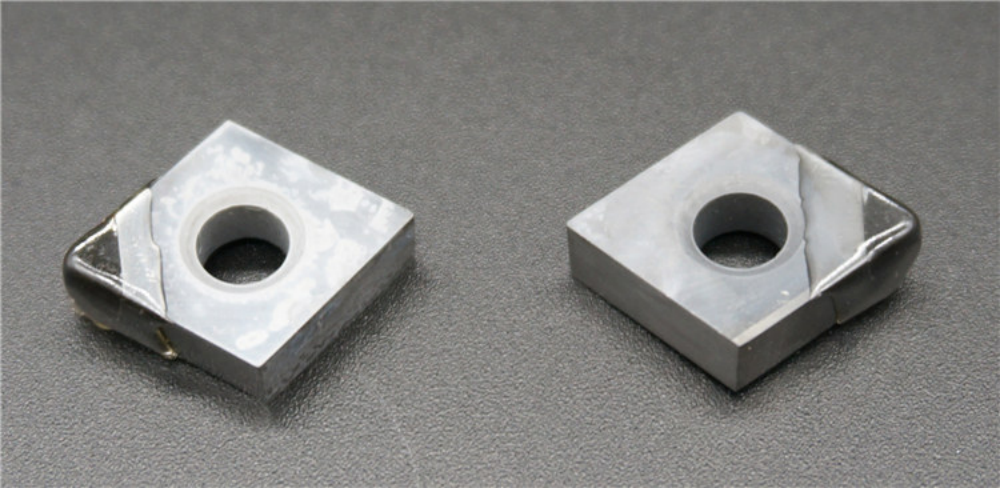

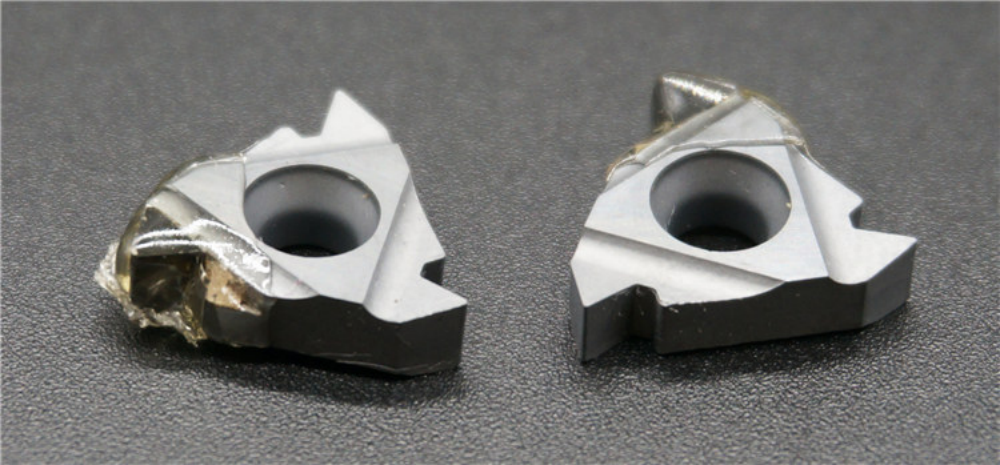

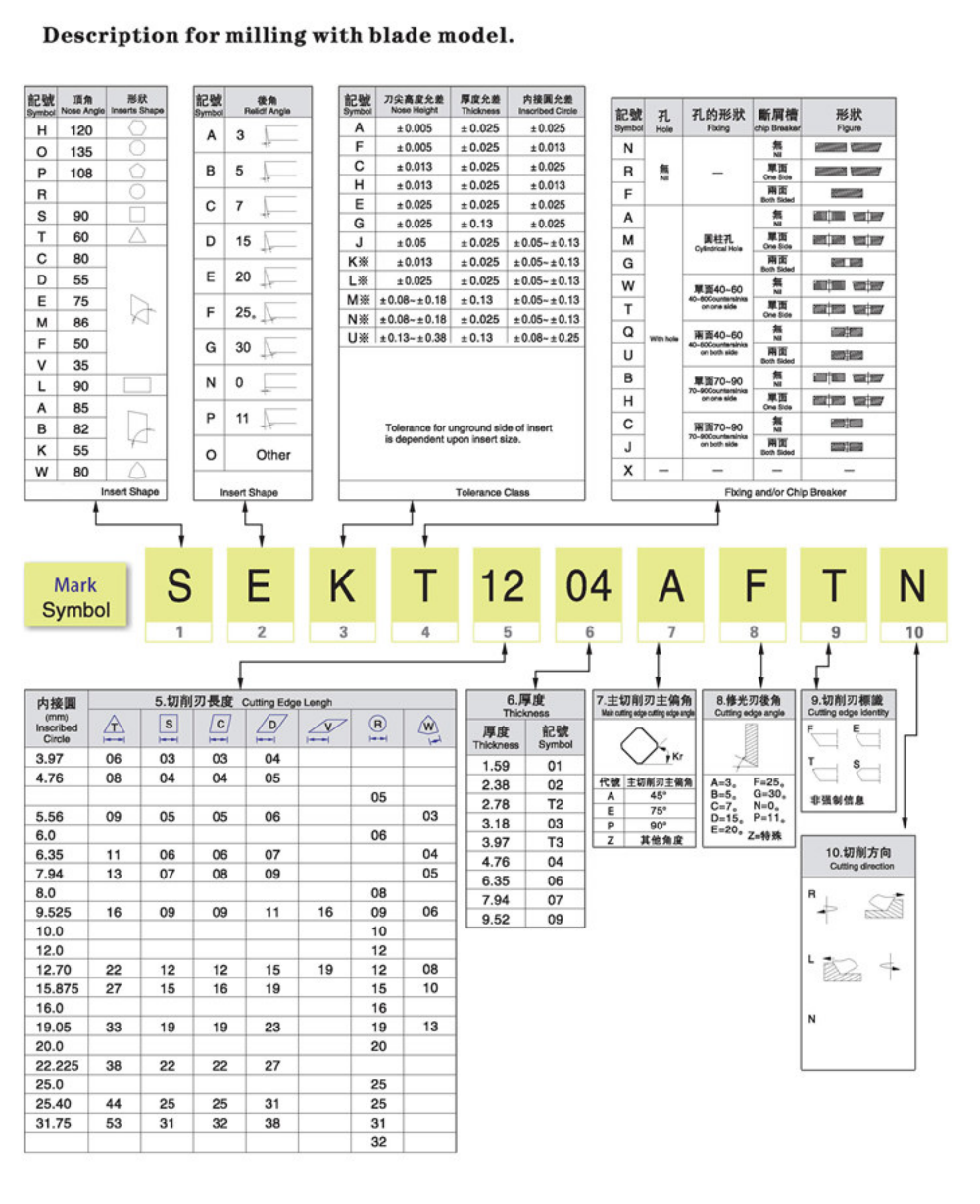

As a full-line supplier of metalworking tools, Xinfa provides a full ISO range of quality tools. All standard geometries are supplied, including the most popular trigon shape. These semi-triangular turning inserts are used for axial and face turning and feature three 80° corner cutting edges on each side of the insert.