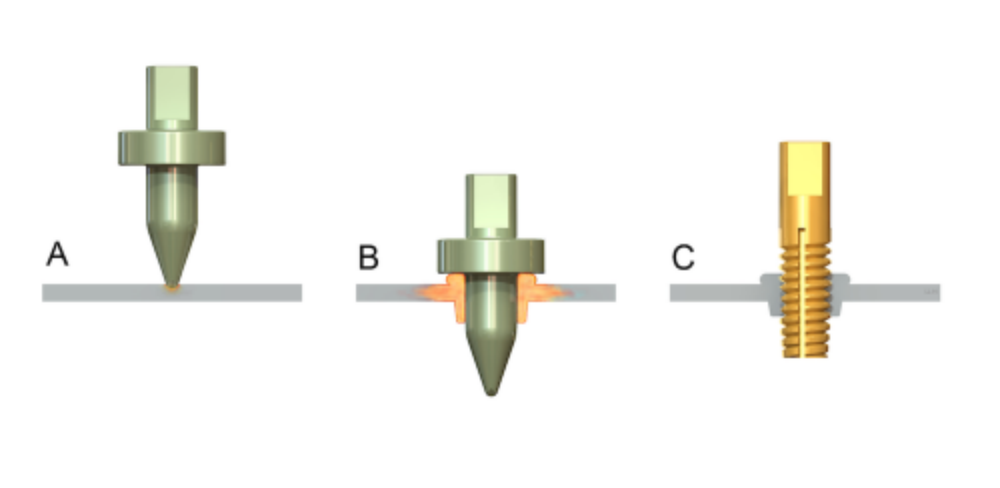

The hot-melt drill generates heat through high-speed rotation and axial pressure friction, plasticizes the material, and at the same time punches and forms a bushing about 3 times the thickness of the raw material. Precision, high-strength threads. It effectively solves the problem of tapping thin plate, square tube and round tube parts and improves the connection strength; it does not need to use simplified spot welding, nuts and washers, which simplifies the processing sequence, and has high precision, thereby reducing the scrap rate of products and saving money. Cost of production.